Post-harvest technology encompasses all aspects from crop maturity to consumption, including processing, distribution, and marketing. It is crucial to process cinnamon hygienically to preserve its taste and aroma.

Harvesting

The first harvest of a cinnamon plantation can typically be undertaken two to three years after planting. At this stage, the outer bark of the stems suitable for harvesting should be completely brown, except for the ends.

In Sri Lanka, the timing of cinnamon harvesting varies across different agroecological zones. Cinnamon trees begin growing new leaves with the onset of the rainy season. The optimal time for harvesting is when these leaves turn green, as the bark peels more easily at this stage. Harvesting should be avoided when cinnamon trees have new leaves, flowers, or fruits, as removing the bark becomes more challenging.

Under good management conditions, cinnamon can be harvested two to three times a year. Increasing the interval between harvests may lead to maturation of the cinnamon stems, resulting in a higher wood percentage but not necessarily a significant increase in bark weight. This can reduce the ability to produce high-quality cinnamon grades such as Alba and C grade. Hence, maintaining the plantation for continuous year-round harvesting is important.

How to Harvest

The propoer method to harvest a cinnamon tree involves making a clean, sharp cut at a 45-degree angle towards the bush, approximately one and a half to two inches (1 ½ – 2 inches) above the ground. This technique promotes the outward growth of new shoots and helps maintain the health of the bush. During harvesting, it is essential to remove any green, immature parts, side branches, and leaves from the cut cinnamon stem in the field before taking them to the peeling shed or processing center.

Knotting and Scraping

The brown outer bark (‘Sumbula’/ ‘Kurutta’) should be scraped from the stem while keeping it above ground level to minimize contaminants, using a scraper.

How to peel cinnamon bark

The scraped stems are rubbed with a brass rod until the juice oozes out and loosens the bark from the wood. Then, determine the width of the outer sheaths to be removed based on the desired grade. Use a small knife called ‘Thalana Kokeththa’ to remove the outer sheaths. If it’s not possible to remove the bark as outer sheaths, peel it off in thin strips called ‘Podi’.

How to Dry the Bark

The outer sheath should be shade-dried until it reaches the desired extent of curling. Ensure that the bark strips or ‘Podi’ are kept clean to prevent excessive drying.

Making Quills

After drying the peeled bark and rolling them as required, stack the bark sheets on top of each other and fill them with small pieces to form 42- or 21-inch-long quills. Use a ‘Pethi Kotuva’ to measure the length of the cinnamon quills. Once completed, immediately shade-dry the quills. Allow the prepared quills to dry on strings, racks, or nets for 4-7 days until their moisture content reaches 14% or below.

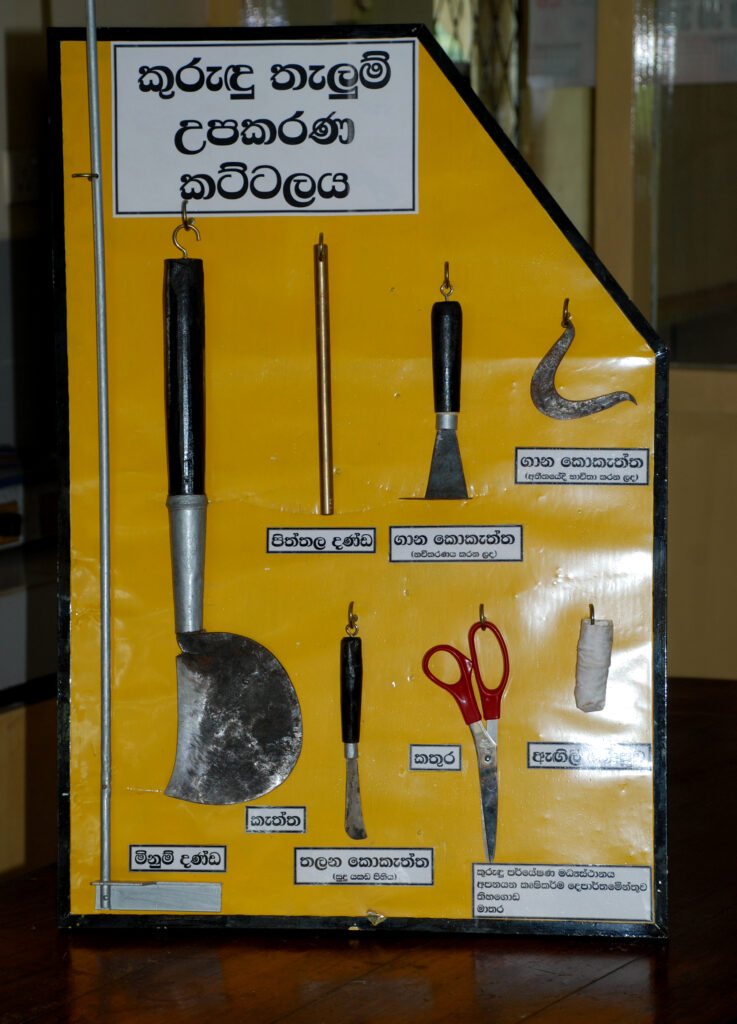

Equipment Used to Process Cinnamon

The tools and equipment used in the traditional cinnamon-making process include:

- ‘Keththa’ – Used for cutting cinnamon trees.

- ‘Surana Koketta’ – For scraping the outer bark (‘Kurutta’).

- Brass rod – Used for rubbing to detach the bark from the wood.

- ‘Thalana Koketta’ – For making vertical and horizontal cuts and lifting the bark while detaching it from the wood.

- Scissor – Used to cut/ and prepare the cinnamon bark after joining it to the desired length.

- ‘Pethi kotuwa’ – Used to measure 42 or 21 inches in length.

Cinnamon Grades:

- Cinnamon quills should be graded after drying to the required level.

- There are three important criteria in grading:

- Diameter of cinnamon quill

- Number of sticks of that diameter required to make one kilogram

- Percentage of foxing on the surface of quills

The criteria outlined above allow for the identification of approximately 13 grades of cinnamon. In general practice, cinnamon can be categorized into two main types:

- ‘Heen Kurundu’ (Smooth Cinnamon): Includes cinnamon in the Alba and ‘C’ groups.

- ‘Gorosu Kurundu’ (Coarse Cinnamon): Includes cinnamon in the ‘M’ and ‘H’ groups.

Growers should aim to produce a higher percentage of ‘Heen Kurundu’ to increase their income.

Standards for Cinnamon:

The demand for healthy, high-quality ingredients and food products is increasing every day. To meet this demand, it is essential to adhere to Good Agricultural Practices (GAP) in cinnamon cultivation and Good Manufacturing Practices (GMP) in cinnamon processing. By doing so, the health and safety quality of the product can be improved.

In 2022, Sri Lanka obtained the Ceylon Cinnamon Geographical Indication (CCGI), an international quality certificate for cinnamon. This achievement provides an opportunity to fetch a higher price for Ceylon Cinnamon in the global market. The CCGI also confirms the Sri Lankan geographical identity of cinnamon, marking the first Geographical Indication for Sri Lanka, which will help overcome future challenges in the Sri Lankan cinnamon market.

The Sri Lanka Standards Institute has introduced a standard for Sri Lankan cinnamon as SLS 81:2021. Similarly, the International Organization for Standardization (ISO) has established requirements and introduced a standard for Sri Lankan cinnamon under ISO 6539:2014. Additionally, the European Spice Association, United States Food and Drug Administration, and other organizations have also introduced applicable standards in their respective countries.

Cinnamon Yield:

The yield of cinnamon can vary widely based on factors such as the age of the plantation, soil quality, climate, genetics, and crop management practices. Currently, the average yield of cinnamon quills in Sri Lanka is about 300 kg per acre per year. Under good management conditions, this yield can be increased to up to 450 kg per acre. With proper crop maintenance and timely care, utilizing new varieties such as ‘Sri Wijaya’ and ‘Sri Gemunu’ introduced by the Cinnamon Research Center, this yield can be further increased to 600 kg per acre by adopting good agricultural practices.

In addition to bark harvesting, approximately 4000 kg of cinnamon leaves can be obtained from one acre per year. Additional income can be earned by extracting leaf oil from these leaves.

Cinnamon Products

- Cinnamon Quills (Whole Quills)

Stems from fully matured cinnamon plantations undergo a process in which the inner bark is removed and then divided into several pieces. These pieces are joined together and filled with smaller pieces of the same type of cinnamon, then left to dry. Each quill measures 105 cm (42 inches) in length. Cinnamon quills are categorized into different grades as outlined in Table 1.1.

Table 1.1: Cinnamon Grades

Grade | Width of Bark to be Removed (mm) | Diameter of the Quill (mm) | Number of 42-inch Quills per Kilogram | Percentage of Foxing (%) |

Alba | 22 | 6 | 45 | 10 |

Continental |

|

|

|

|

C5-Extra Special | 28 | 8 | 33 | 10 |

C5- Special | 35 | 10 | 30 | 10 |

C5 | 42 | 12 | 27 | 15 |

C4 | 54 | 16 | 22 | 15 |

C3 | 61 | 18 | 20 | 20 |

Mexican |

|

|

|

|

M5- Special | 54 | 16 | 22 | 60 |

M5 | 60 | 18 | 20 | 60 |

M4 | 70 | 21 | 15 | 60 |

Hamburg |

|

|

|

|

H1 | 76 | 23 | 10 | 25 |

H2- Special | 83 | 25 | 09 | 40 |

H2 | 105 | 32 | 07 | 55 |

H3 | 123 | 38 | 06 | 65 |

- Cut Quills – Cinnamon sticks cut to a specified length and graded as whole cinnamon sticks.

- Quilling – Whole cinnamon sticks broken into pieces less than 200 mm in length. They may contain up to 5% by weight of feathers and bark pieces. No other foreign substances should exceed 2%.

- Featherings – Small pieces that break off from cinnamon bark when making cinnamon quills. They may contain up to 10% chips by weight, with other extraneous substances not exceeding 2%.

- Chips – Mature, hard, greenish-brown bark with an outer layer called ‘Kurutta’ that cannot be peeled off conventionally. It must be separated by scraping or beating with a wooden stick. Chips should not contain more than 2% of other extraneous substances.

- Ground Cinnamon – Cinnamon powder prepared by drying and grinding the inner bark from well-ripened cinnamon stalks. 100% of particles should be smaller than 500 micrometers, and 90% should be smaller than 300 microns.

- Crushed Cinnamon – Coarse cinnamon powder prepared by drying and grinding the inner bark from well-ripened cinnamon stalks. 90% of particles should be larger than 500 micrometers.

- Special Cuts – Inner bark from well-ripened cinnamon stalks, dried and cut into small pieces ranging from 1 mm to 5 mm.

Cinnamon Value-added Products

Cinnamon possesses significant medicinal value and is a key ingredient in many therapeutic products. It is known for its efficacy in managing conditions like diabetes and hypertension by regulating blood sugar and cholesterol levels. Its antioxidant properties also make it beneficial for combating various diseases.

Beyond its medicinal applications, cinnamon serves as a versatile flavoring agent in sweets, beverages, and bakery products. It is also utilized in perfumes due to its aromatic qualities. Moreover, cinnamon’s natural anti-fungal and anti-bacterial properties make it suitable for inclusion in oral care products such as mouthwash and toothpaste.

Cinnamon Essential Oil:

Various essential oils can be extracted from the cinnamon plant, particularly from Sri Lanka’s Cinnamomum verum, which is highly esteemed globally, contributing to its profitability. The primary oil-based products derived from the cinnamon plant include cinnamon leaf oil and cinnamon bark oil. However, commercial extraction of oil from cinnamon fruits and roots is not commonly practiced.

Cinnamon Leaf Oil Extraction:

Cinnamon leaf oil boasts an oil content that can reach up to 4%. The leaves and shoots removed during cinnamon harvesting serve as the primary raw materials, with preference given to ripe and shredded leaves.

- Yield of Leaves: 10,000 kg per hectare per year

- Average Oil Yield (Industrial): 1% (from mass of leaves)

- Annual Oil Yield (Industrial): 100 – 200 kg per hectare per year

Cinnamon leaf oil can be extracted using various methods, including:

- Hydro distillation

- Steam-hydro distillation

- Steam distillation

Despite the development of modern technologies such as supercritical CO2 extraction, microwave extraction, and ultrasonic wave extraction, these methods are not widely utilized in industrial applications. Consequently, steam distillation remains the primary method for extracting cinnamon leaf oil.

Benefits: Cinnamon leaf oil finds application in the production of perfumes, insect repellents, disinfectants, fragrances, and medicines.

Standards for Cinnamon Leaf Oil:

- SLS 184-2012: National standard for cinnamon leaf oil

- ISO 6579:2003: International standard for cinnamon leaf oil

These standards define the physical and chemical criteria that cinnamon leaf oil must meet for quality assurance.

Cinnamon Bark Oil Extraction:

Cinnamon bark contains an oil content ranging from 3.0% to 4.0%. Raw materials for oil extraction include pieces of cinnamon quills (Quilling), Featherings, and Chips (‘Katta’). The percentage of Cinnamaldehyde in the oil varies based on the raw materials used, determining the classification of the bark oil.

Character | Requirements | |||

Superior Grade | Special Grade | Average Grade | Ordinary Grade | |

Cinnamaldehyde (% by weight) | Above 60 | 55-60 | 45-54 | 30-44 |

Eugenol (% by weight) | 6 | 15 | 25 | 40 |

Standards for Cinnamon Bark Oil:

- SLS 185-2012: This is the national standard for cinnamon bark oil, specifying the physical and chemical criteria that the oil must meet for quality assurance.

Benefits:

Cinnamon bark oil serves as a popular flavoring agent in the production of confections and beverages. Additionally, it finds use in the manufacturing of various perfumes and medicines.

Oleoresins Production:

Oleoresins are semi-solid extracts containing both resin and volatile oil components, obtained through various extraction methods:

- Solvent Extraction: This method involves using solvents to extract both resin and volatile oils from cinnamon materials.

- Supercritical Carbon Dioxide (CO2) Extraction: Utilizes supercritical CO2 as a solvent to extract essential oils and other compounds from cinnamon, known for its efficiency and ability to preserve delicate flavors and aromas.

- Microwave Extraction: A modern method utilizing microwave technology to extract essential oils and compounds from cinnamon, offering faster extraction times and potentially better preservation of volatile components.

Applications of Cinnamon Oleoresin:

Cinnamon oleoresin finds extensive use across various industries due to its potent flavor and aroma profile:

- Food Industry: Used as a flavoring agent and food coloring in products like confectioneries, beverages, and sauces.

- Perfumery: Adds fragrance notes in perfumes and cosmetic products.

- Pharmaceuticals: Incorporated into pharmaceutical formulations due to its medicinal properties.

- Cosmetics and Soaps: Used for fragrance and as an active ingredient in cosmetic and soap formulations.

Each extraction method offers distinct advantages in terms of efficiency, product quality, and environmental impact, catering to different industry needs and regulatory standards.